How 3D Printing Is Transforming the Manufacturing Industry

The advent of 3D printing technology has initiated a profound shift within the manufacturing sector, enabling processes that were previously unfeasible. By facilitating rapid prototyping and on-demand production, companies can now effectively respond to market demands while minimizing waste and costs. This transformative approach is particularly evident in industries such as aerospace, automotive, and healthcare, where customization and efficiency are paramount. However, as the landscape of manufacturing continues to evolve, one must consider the implications and potential future developments that could further reshape this industry. What lies ahead may redefine our understanding of what is possible in manufacturing.

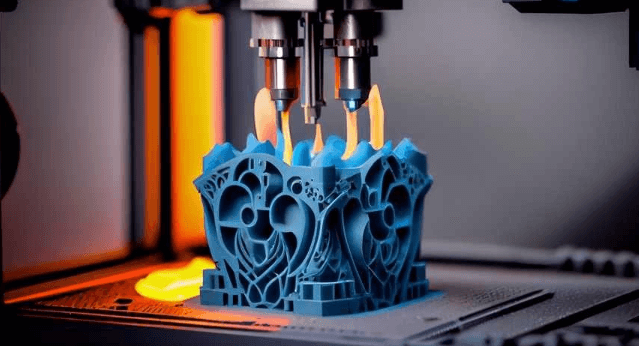

Overview of 3D Printing Technology

3D printing technology, also known as additive manufacturing, has revolutionized the production landscape by enabling the creation of complex geometries directly from digital models.

This approach allows for rapid prototyping, significantly reducing the time and cost associated with traditional manufacturing methods.

Benefits for Manufacturers

The integration of additive manufacturing into production processes offers manufacturers a multitude of advantages that enhance operational efficiency and product quality.

Notably, cost reduction is achieved through minimized material waste and streamlined production timelines.

Additionally, design flexibility allows for intricate geometries and customized solutions, enabling manufacturers to respond swiftly to market demands while fostering innovation in product development and reducing lead times significantly.

Applications Across Industries

Additive manufacturing has found diverse applications across various industries, demonstrating its versatility and transformative potential.

In the medical sector, it produces bespoke medical devices, while aerospace components benefit from lightweight designs.

Automotive prototyping and customized tooling enhance production efficiency.

Additionally, it enables innovative consumer products, architectural models, and educational purposes, as well as unique fashion accessories, highlighting a broad spectrum of creative possibilities.

Future Trends in 3D Printing

Emerging trends in additive manufacturing are poised to redefine the landscape of production and design across multiple sectors.

The integration of sustainable materials and efficient processes will enhance the sustainability impact of 3D printing.

Furthermore, advancements in design innovation will enable complex geometries and customized solutions, driving competitive advantages.

These developments signify a transformative shift toward more responsible and agile manufacturing practices.

Conclusion

In summary, 3D printing stands as a pivotal force reshaping the manufacturing landscape, akin to a sculptor chiseling intricate designs from a solid block of marble. This technology not only streamlines production processes but also fosters innovation through its ability to create bespoke solutions tailored to specific needs. As industries embrace this transformative power, the horizon gleams with possibilities, promising a future where imagination and functionality coalesce, ultimately driving sustainability and efficiency in manufacturing practices.