Precision and Performance: The Role of Custom Bolts and Fasteners in Modern Engineering

Introduction

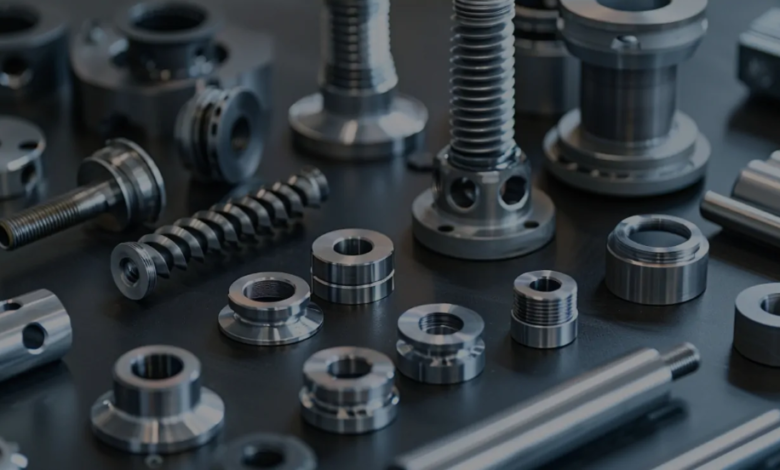

In today’s advanced engineering and manufacturing landscape, the demand for precision components has reached an all-time high. Among these critical components, custom bolts and fasteners play a vital role in ensuring structural integrity, reliability, and safety across various industries. From aerospace and automotive to construction and renewable energy, the requirement for tailored fastening solutions has become a norm rather than an exception. This article explores the increasing importance of custom bolts and fasteners, their applications, benefits, and what to consider when sourcing them.

Understanding Custom Bolts and Fasteners

Custom bolts and fasteners are fastening components that are manufactured to meet specific dimensional, material, or performance requirements. Unlike standard fasteners that come in fixed sizes and materials, custom options are designed based on unique application demands. These components are engineered to address special conditions such as extreme temperatures, high stress, vibration resistance, or corrosive environments.

Fasteners include a wide variety of hardware like bolts, screws, nuts, washers, studs, and pins. When custom-built, each of these elements contributes to the overall durability and performance of machinery, structures, and equipment.

Key Industries That Rely on Custom Solutions

Several high-demand industries depend heavily on custom bolts and fasteners due to their specialized operations:

Aerospace

The aerospace sector requires fastening systems that can withstand drastic temperature changes, intense vibrations, and high stress. Here, weight reduction and strength are both critical. Custom bolts and fasteners ensure compliance with stringent safety regulations and reliability standards.

Automotive

From performance vehicles to electric cars, automotive manufacturers seek custom components to ensure that every bolt fits perfectly with minimal tolerance. They are crucial in engine assembly, body frames, and safety features like airbags and seatbelts.

Construction and Infrastructure

Bridges, skyscrapers, and tunnels rely on durable fastening systems that resist corrosion and environmental damage. Custom bolts and fasteners designed for such applications often come with special coatings or are made from high-strength alloys.

Oil and Gas

In this industry, fasteners must resist extreme pressure, chemical exposure, and varying temperatures. Custom-built hardware is designed to function effectively in offshore platforms, drilling rigs, and pipelines.

See also: How to Protect Yourself From Misuse of AI Face Swap Technology

Benefits of Custom Bolts and Fasteners

Enhanced Performance

Custom fasteners offer superior performance compared to generic options. By tailoring the dimensions, material, and finish, they can better withstand operational stresses and last significantly longer.

Precision Fit

Every piece of equipment is different, especially when it comes to OEM (Original Equipment Manufacturer) systems. Custom bolts and fasteners provide a precise fit that reduces wear and minimizes the risk of failure.

Compliance with Industry Standards

Custom fasteners can be manufactured to meet exacting industry standards and certifications such as ASTM, ISO, or DIN, ensuring safety, compatibility, and traceability.

Cost Efficiency in the Long Run

While custom fasteners may have a higher upfront cost than off-the-shelf options, their durability and reduced maintenance needs make them cost-effective over time. They also help prevent costly downtime caused by component failures.

Materials Used in Custom Manufacturing

Choosing the right material is a key aspect of producing effective fasteners. Depending on the application, manufacturers may use:

- Carbon steel: Ideal for general-purpose fasteners

- Stainless steel: Offers excellent corrosion resistance

- Titanium: Lightweight and strong, perfect for aerospace and marine

- Brass and bronze: Common in electrical and decorative applications

- Exotic alloys: For highly specialized applications like nuclear or deep-sea environments

Each material is selected based on mechanical strength, chemical resistance, thermal conductivity, and environmental compatibility.

Manufacturing Techniques

Modern manufacturing methods allow for highly accurate and consistent production of custom bolts and fasteners. Some of the most common techniques include:

CNC Machining

CNC machines offer incredible precision, making them ideal for small-batch or highly specialized fasteners.

Cold Forging

Used for producing strong and durable bolts at high speed, this method shapes the fastener without heat, maintaining the integrity of the material.

Thread Rolling

This process enhances the strength of the fastener by shaping threads without cutting them, which helps prevent fractures and cracks under stress.

Heat Treatment

To achieve specific mechanical properties like hardness and toughness, fasteners often undergo heat treatment after forging or machining.

Selecting the Right Supplier

Choosing the right supplier for custom bolts and fasteners is critical for project success. Here are key considerations:

Engineering Support

Look for suppliers who offer in-house engineering support. They can assist with material selection, design optimization, and cost-effective manufacturing.

Quality Assurance

Check if the supplier provides quality documentation, inspection reports, and certifications. These are essential for ensuring consistency and traceability.

Turnaround Time

Timely delivery can make or break a project timeline. Opt for manufacturers with efficient production schedules and supply chain management.

Scalability

Whether you’re producing a prototype or planning mass production, the supplier should have the capacity to scale according to your needs.

Sustainability and Custom Fasteners

Sustainability is now a core concern across industries. Custom bolts and fasteners contribute to sustainability by minimizing waste through precise design, using recyclable materials, and enabling longer equipment life spans. Many manufacturers now implement eco-friendly processes, like water-based lubricants, energy-efficient machinery, and waste recycling systems.

Common Challenges in Custom Fastener Projects

While custom bolts and fasteners provide numerous advantages, they also come with challenges:

- Higher initial cost due to engineering and tooling

- Longer lead times for design and manufacturing

- Risk of rework if design specifications are not accurately defined

These issues can be mitigated by partnering with experienced manufacturers who follow a structured design and production process.

Conclusion

In a competitive global market, where product performance, safety, and efficiency are critical, custom bolts and fasteners serve as foundational custom bolts and fasteners elements across multiple industries. They offer unmatched advantages in terms of precision, durability, and application-specific customization. Choosing the right partner for your fastening needs ensures that your components are engineered to meet exact specifications, enhancing both the integrity and longevity of your projects.

Whether it’s a lightweight aerospace component or a high-tensile anchor bolt for a bridge, custom solutions are the way forward. Investing in tailored fasteners today means ensuring success, safety, and savings for the future.